We provide a wide range of technical services related to the preservation of all types of reinforced concrete structures and specialize in diagnostic evaluation, provide recommendations for and design repair and rehabilitation.

CONCORR, Inc. are corrosion industry pioneers and have developed a unique mathematical model in 2005 to project future concrete damage resulting from the corrosion of reinforcement. This model has been used on numerous projects for several Departments of Transportations and Private Clients to identity cost-effective long-term repair and rehabilitation solutions. The model has also been used as a decisive factor in corporate litigation to determine the amount of damage that resulted due to negligence.

About

CONCORR, Inc. was established in 1990 to develop technologies and provide solutions for mitigating corrosion of reinforcement, both conventional and stressed, in reinforced concrete structures.

It specializes in diagnostic evaluation, developing cost-effective strategies for extending the service life for the desired length of time, and designing the corrosion mitigation systems that can accomplish it.

The company has successfully performed numerous research and development programs in all areas of corrosion of reinforcement in concrete for various National Agencies. These projects have been funded by the Federal Highway Administration (FHWA) under the Strategic Highway Research Program (SHRP) and the Long-Term Pavement Program (LTPP), the US Department of Transportation under the Small Business Innovation Program (SBIR), the National Academy of Sciences under the National Cooperative Highway Research Program (NCHRP), and several others. The experience and understanding obtained from these projects are brought to bear upon the structural preservation projects the company is involved in.

An innovative mathematical Service Life Model was developed under one of these research projects. The model has been used by the company since 2005 to project future damage based on the present condition of the structure and used in the development of cost-effective preservation solutions. The results of the model have been used by several State Departments of Transportations, such as the Florida DOT, Virginia DOT, New Jersey DOT, Washington State DOT, and many private clients.

CONCORR, Inc. designed the first full scale galvanic cathodic protection system to be installed on pre-stressed marine piles in 1990. This groundbreaking technology has become standard practice now. It was one of the first to incorporate both infra-red and ground penetrating radar technologies in corrosion condition evaluations. The company developed the first automated system to acquire and process infra-red surveys to identify delaminations under the FHWA “Demonstration Project 84” in the early 1990s. It also developed a mathematical model to estimate the distribution of current in an impressed current cathodic protection system.

Ali Akbar Sohanghpurwala

Principal

M.S., Ocean Engineering – Florida Atlantic University

B.Tech., Naval Architecture – Indian Institute of Technology Madras, India

NACE Certified Corrosion Specialist (#4422) since 1992

NACE Certified Cathodic Protection Specialist (#4422) since 1992

NRMCA Certified Concrete Technologist since 1988

Ali Akbar Sohanghpurwala is one of the founders of CONCORR, Inc. He is recognized as one of the top professionals in the country dealing with corrosion of metals in concrete. With over 35 years of experience, he is an expert in all areas of corrosion mitigation technology, and has been fortunate enough to be involved in the entire spectrum of the corrosion mitigation industry. His experience and expertise in research and development of corrosion condition evaluation and mitigation technologies is well supplemented by his experience in the everyday use of these technologies in the field.

He developed the protocol for bridge condition evaluation and service life modeling under an NCHRP Project and the manual “Service Life of Corrosion-Damaged Reinforced Concrete Bridge Superstructure Elements, NCHRP Report 558,” which was recommended by TRB for adoption by AASHTO. He also developed a mathematical model for distribution of current in an impressed current cathodic protection system.

Consulting Services

Repair & Rehabilitation Solutions

- Diagnostic Condition Evaluation

- Nondestructive Testing

- Data Analysis

- Service Life Modeling

- Recommendations for short-term, medium-term, and long-term repair

Design of corrosion mitigation systems

- Design Galvanic Cathodic Protections Systems

- Design Impressed Current Cathodic Protection Systems

- Design Electrochemical Chloride Extraction Application

QA/QC during installation

We provide Cathodic Protection Specialists Services for:

- Galvanic Cathodic Protection Systems

- Impressed Current Cathodic Protection Systems

- Electrochemical Chloride Extraction

Litigation Services

- Collection of information and structure condition data

- Expert Opinion

- Deposition

- Testimony

Featured Consulting Projects

Jefferson Street Bridge

Performed Condition Evaluation Recommendations for Repair Design of ICCP System QA/QC During Construction Monitoring & Maintaining ICCP

Parking Garage

Performed Condition Evaluation Recommendations for Repair Design of Galvanic CP System QA/QC During Construction

Oceania Resort Aruba

Design of ICCP System QA/QC During Construction Monitoring & Maintaining ICCP

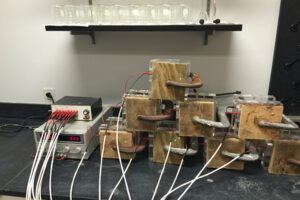

Laboratory Services

Acid Soluble Chloride Ion Analysis

- ASTM C1152

- AASHTO T260

Water Soluble Chloride Analysis

- ASTM C1218

- ASHTO T260

Rapid Chloride Permeability Testing

- AASHT T277

- Virginia VTM-112

- Florida Resistivity Test F1-578

- ASTM C1876

Featured Laboratory Testing Projects

Woodrow Wilson Bridge

Maryland & Virginia

Performed QA/QC using AASHTO T 277 – Rapid Chloride Permeability Testings

Arlington Memorial Bridge

Washington, DC

Tested thousands of samples for acid chloride ion content in accordance with ASTM C1152

I-80 Widening Project Study

New Jersey

Tested over a thousand samples in accordance with ASTM C1152

Contact

agencies